Safe, Compliant and Efficient Water Systems

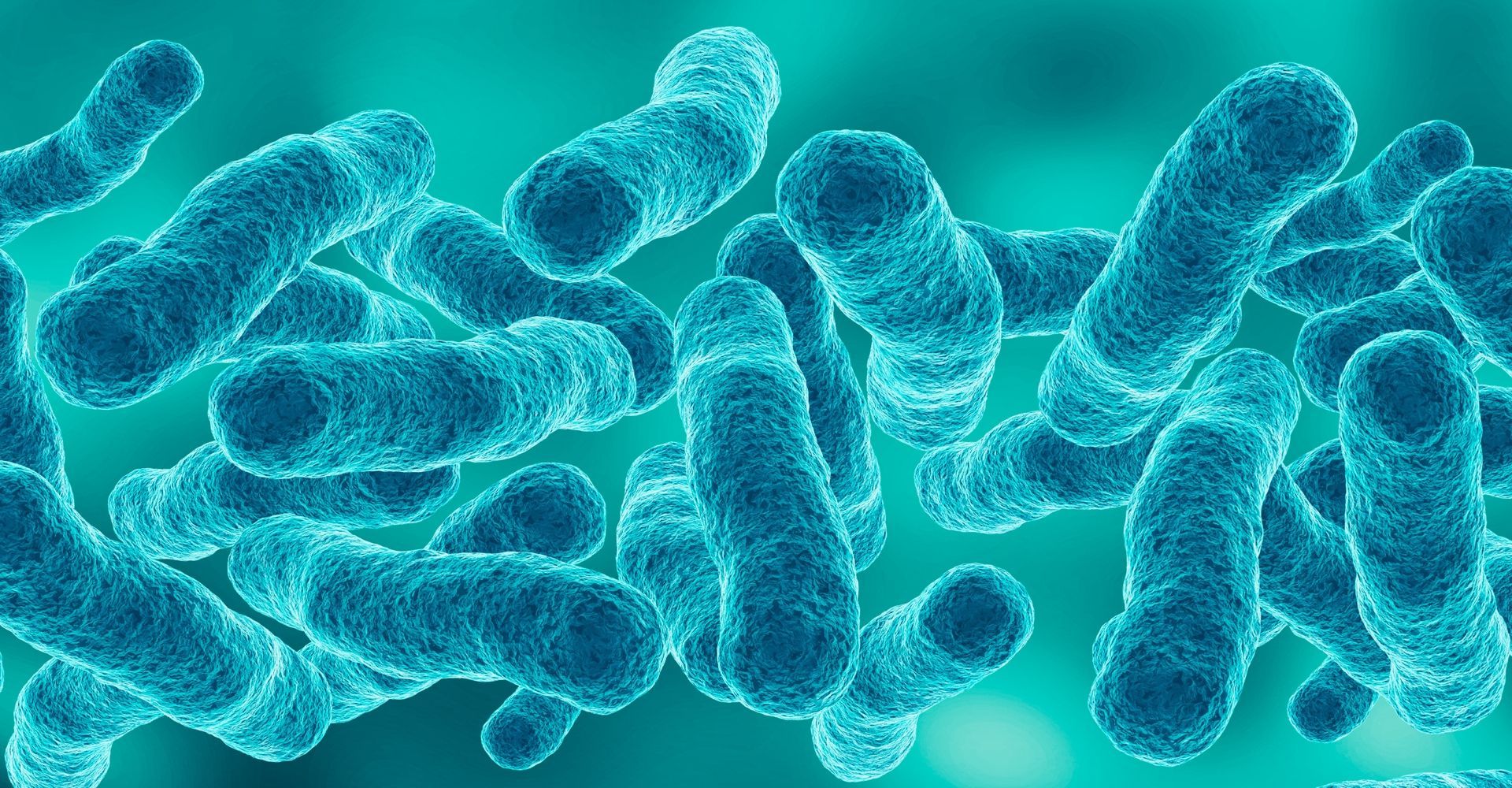

Water systems need to stay clean, balanced and fully compliant to protect people and keep buildings running safely. Regular testing and treatment ensure reliability, efficiency and compliance with HSE ACOP L8 and HSG 274. With structured monitoring and maintenance, your system stays safe, efficient and problem-free long term. Each stage is designed to meet the standards expected as a member of The Legionella Control Association.

Water treatment is delivered by qualified engineers with over 30 years’ experience in compliance and system performance. From disinfection and Legionella testing to closed-system checks, every stage is handled by specialists. All reports, certificates and results are issued electronically — reducing paperwork, improving traceability and cutting your carbon footprint.

How Water Systems Are Treated and Managed

Every process is structured, evidence-based and fully traceable. Testing and documentation are maintained at every stage to prove compliance and protect your system.

- System disinfection before use

- UKAS-approved laboratory analysis

- Corrosion and BG50 closed-system checks

- Steam boiler water treatment

- Routine monthly or quarterly monitoring

- TMV testing and service

- Showerhead cleaning and descaling

- Full HSG 274 records maintained

Why Preventative Monitoring Extends System Life

Unchecked water systems lead to corrosion, bacteria and costly breakdowns. Preventative monitoring identifies early changes in water chemistry before they cause damage. With the right treatments in place, your systems stay efficient, last longer and avoid sudden failures — saving money, reducing risk and improving long-term reliability.

Disinfection Before Building Use

During construction, water systems are exposed to contaminants. Disinfection removes bacteria before occupancy, ensuring the water supply is clean and safe. Once flushed and tested for potable quality, certification is issued. This guarantees compliance and gives complete confidence that the system is ready for safe use and handover.

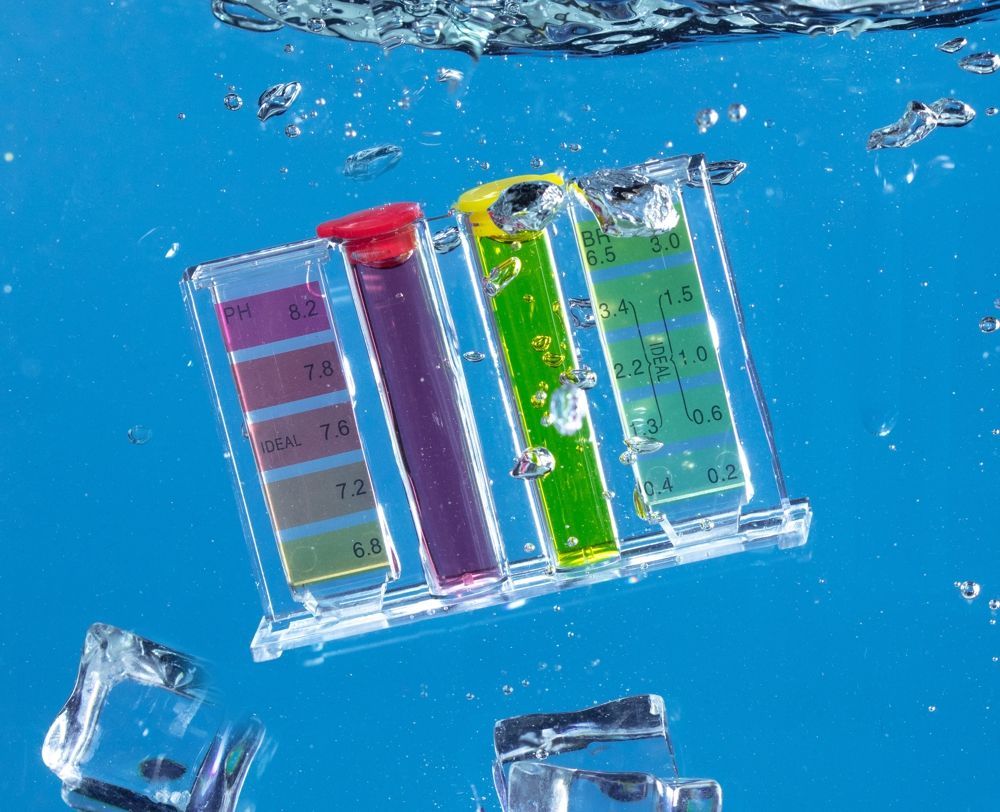

Corrosion Testing and Water Chemistry

Closed-loop heating systems require close attention. Regular checks on pH, iron levels and inhibitor concentration detect early signs of corrosion. Chemical treatment programmes stabilise water chemistry and protect system components. Over time, this improves energy efficiency, reduces wear and prevents costly repairs — supported by full test data and compliance records.

Keeping Systems Safe and Reliable

From new installations to existing systems, water treatment with MACP protects your building, reduces downtime and ensures compliance. Talk to us about creating a maintenance and monitoring programme that keeps your systems clean, safe and performing efficiently all year round.

MACP delivered high-quality M&E works with impressive attention to detail and professionalism — we couldn’t be happier and look forward to working with them again.

Jason Postans – Procurement Manger - Morris Property

MACP provide excellent, reliable M&E maintenance with a proactive approach and responsive 24-hour service — professional, efficient, and highly recommended.

Lewis Rees – Regional Compliance Officer - Wales & West Housing Association